Story #22

Continuing the last story’s What the Heck are Floating (something)? theme, let’s talk about flooring. There are so many products out there and the vocabulary can get confusing. For example, I learned that “laminate” is not the same thing as “vinyl plank flooring” after I sent an estimate with the wrong labor rate and unclear description. Now that Beams to Basements Contractors is approaching our second anniversary, we know more about Front Range homeowners’ flooring choices. We’re focusing our flooring installation services specifically on snap-together products that can be installed as a “floating floor.”

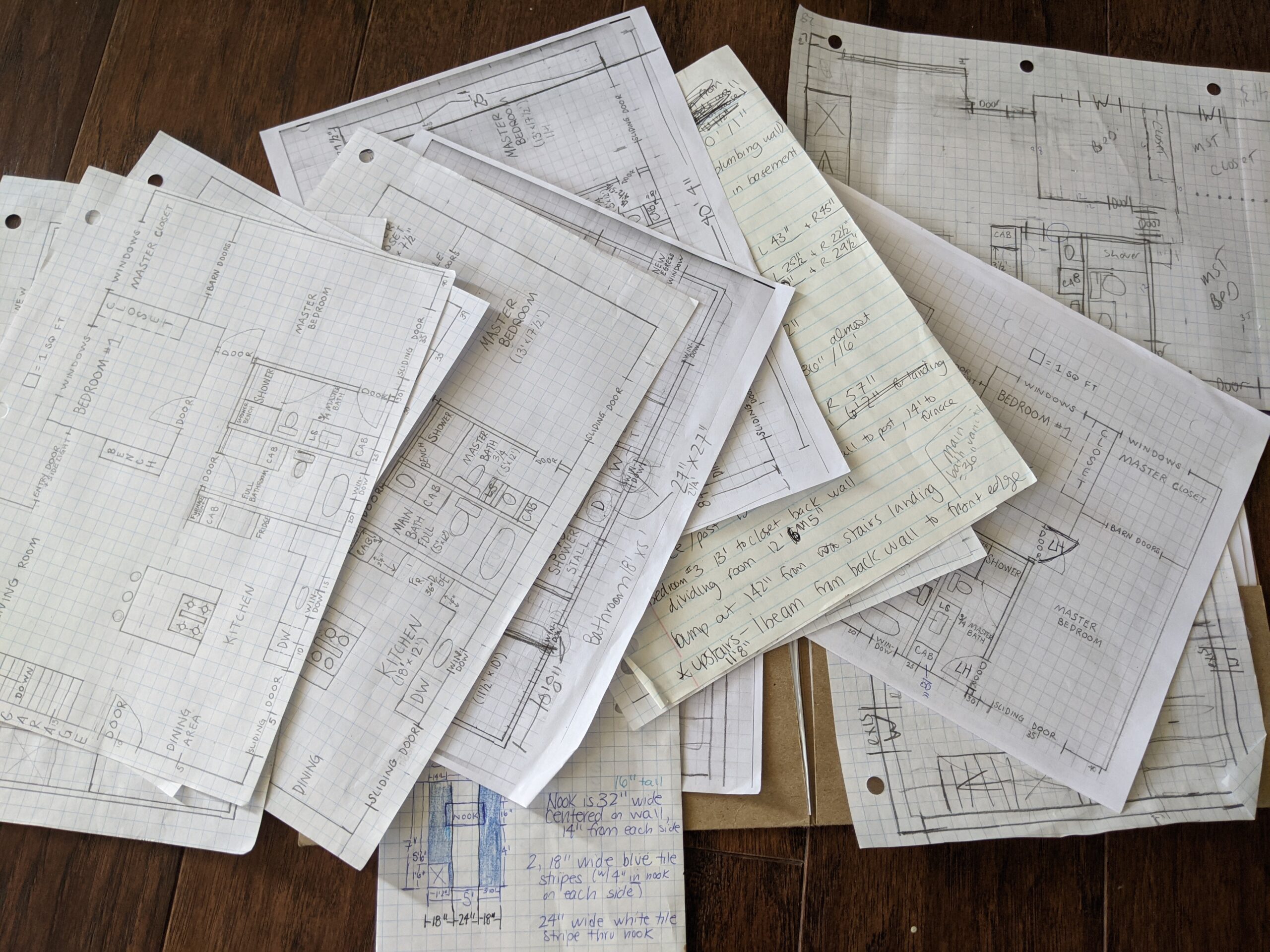

PROJECT NOTES

We picked an engineered hardwood that met those criteria for our living room, hallway, and both main level bedrooms. Although Josh installs this type of flooring, we hired Everett Libby, owner of Mt. Everett Remodeling, LLC, to do all of the floors except the carpeting in our new house. We’re delighted with the finished look! By sharing another story from our first home, we aim to explain this popular remodeling project and why we chose it.

First, what is it? A common misunderstanding is that the term “floating floor” refers to the material, but it’s actually about how the flooring is installed. Lee Wallender gave the following explanation of the installation method in his article, Floating Flooring Review: Pros and Cons: “individual planks (or in some cases tiles) interlock edge-to-edge to form a single mat-like surface that simply rests on the underlayment. It is quite different from the glue-down or nail-down methods that are still used for ceramic and stone tiles, and which were once standard for pretty much all flooring materials.” While many flooring materials offer styles that can be installed this way, including engineered hardwood, laminate, and luxury vinyl plank, not every flooring product made in these materials can be installed this way. When we were shopping, we filtered our search by installation type to ensure we got the right thing.

Second, why did we choose this type of flooring? There are a few solid reasons that homeowners can save labor and materials costs by choosing flooring materials that can be installed “floating.” One major difference is that floating floors are installed on top of most existing floors, like tiles, so there’s no demolition and disposal of the original materials. (Exception: Floating floors cannot be installed on top of carpeting.) This can be a significant saving if you discover carcinogenic asbestos tiles because floating floors can be installed without disturbing the asbestos, eliminating the need to hire a state-certified asbestos abatement company to safely remove and destroy the tiles.

In our first house, we had to consider the costs of materials other than just the flooring product. When we removed or moved most of the walls in our 1970s ranch home, we were left with many gaps in the subfloor from where the walls had been. If we wanted to use flooring materials that attach to the subfloor, we would have had to make it completely level by installing approximately 700 SQ FT of plywood on top of the existing subfloor. Because lumber prices were skyrocketing as we were picking our materials (Fall 2020), the cost for the new subfloor alone made it too expensive for us to consider any other installation method than floating.

Not only can you save time and money by not removing the original floors, but the installation time will also be shorter because floating floors don’t require fasteners. The snap-together, tongue-and-groove engineering allows planks to easily slide together, making it a popular do-it-yourself project, too. Plus, it’s easier to just replace damaged planks than if they’re nailed and/or glued down. Instead of being stuck in place, there is some “give” or bounce in floating floors, allowing them to expand and contract when the moisture level in your house changes. Some people complain that this flexibility makes floating floors feel hollow when you walk on them. The quality of the materials you buy and skills of the installer can minimize how noticeable this movement is. Engineered hardwood, in particular, can take several months to settle into place.

THINGS WE LEARNED

I learned a lot about flooring products as I shopped and collected bids from different flooring companies. Engineered hardwoods are topped with real wood which is why they feel more natural than vinyl plank floors. The flooring we bought has a thick enough top layer (2mm) that we can refinish the dull surface just like solid hardwood floors at least once before replacing them—more savings! I was drawn to the bamboo flooring products because I thought it was a more sustainable product, but luckily, a few people steered me away from them because bamboo doesn’t perform well in Colorado’s intense climate. The flooring manufacturers also change the style and size of the bamboo planks every few years. Instead of finding a perfect match when you need to make a small repair a few years after the floors are installed, you may need to replace the entire floor. Finally, don’t cheap out on the underlayment if your flooring needs it. On the other hand, some floating floors don’t require underlayment because there’s cork on the bottom of the pieces. Read the product specifications and talk to the salespeople and installer (if you’re not doing it yourself) to buy the right materials for the best finished look.